1908

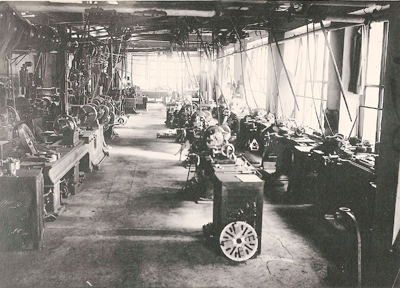

The Carl Semper & Co. company was founded by Carl Semper and Robert Scheffel. Operations begin with the production of wire processing machines.

1915

Carl Semper leaves the company - Robert Scheffel becomes the sole owner.

1938

Robert Scheffel's 3 sons Rudolf, Hermann and Ernst Scheffel join the company

1948

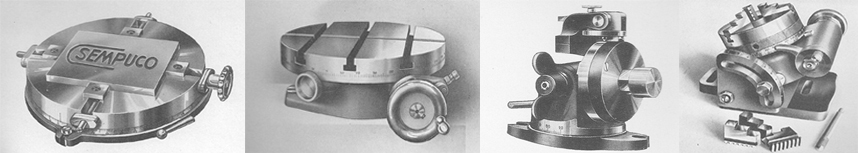

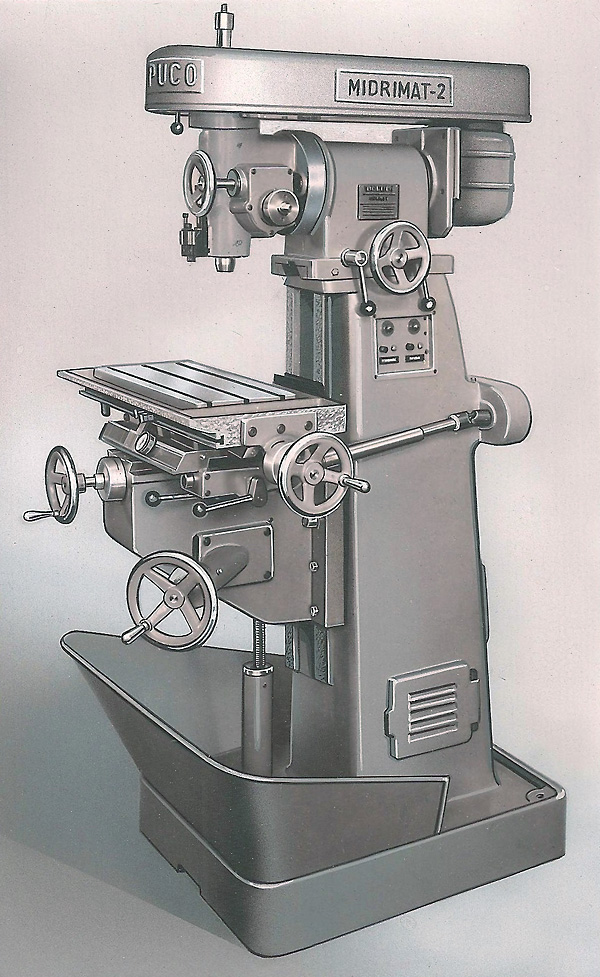

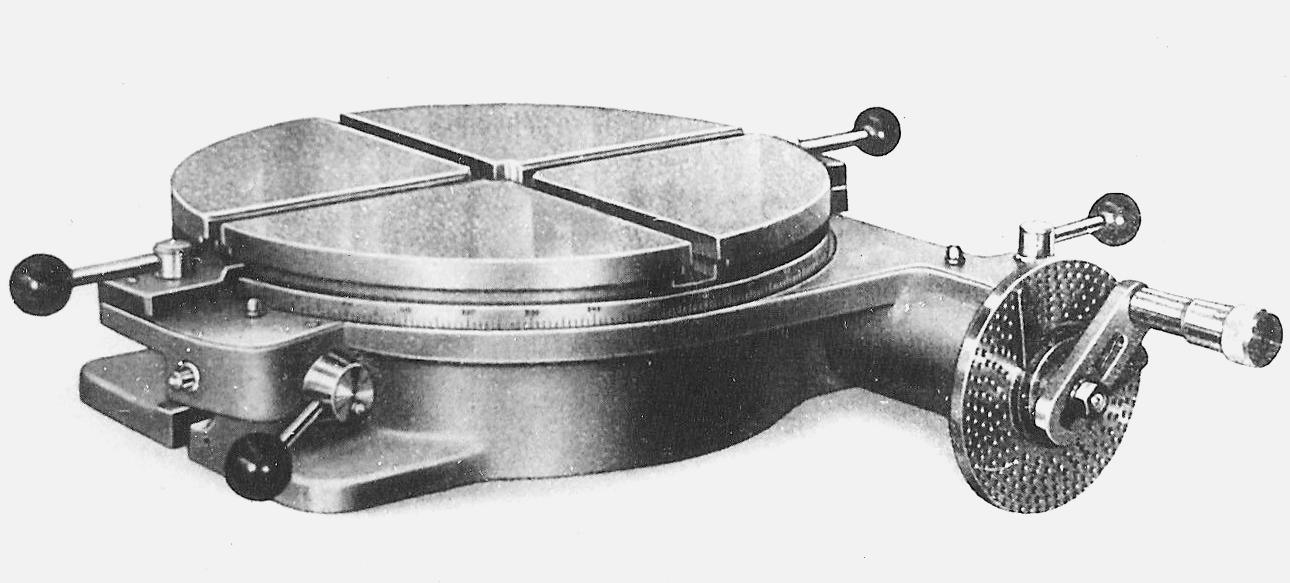

Development and manufacture of precision, milling and boring machines for toolmaufacturing and fixture construction, thereby expanding the rotary table programme

1951

Starting the production of roundtable RT 34

1965

Start of mass production of rotary tables. Sempuco becomes a specialist company for the manufacture of rotary tables within the Fritz Heckert milling machine combinewith the intention of covering the East German market on its own. The wire processing machine programme is relocated to other companies for reasons of capacity.

1972

Development and construction of NC rotary tables.

1973

Sempuco is nationalised.

1977

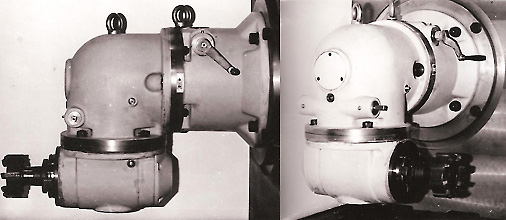

Sempuco constructs a dual axis universal milling head for boring mills and so beginsthe development of a wide-ranging selection of milling heads

1990

As of 01.07.1990, Sempuco is returned to family ownership as part of the reprivatisation programme. Thomas Scheffel, a grandson of the founder, assumes the position of Managing Director.

– immediate continuation of the development of the product range programme.

– development of a company-internal sales structure

All this achieved without any external participation or liquidity assistance from the State

1992

Thomas Scheffel takes over the State's share of the company.

1994

Sempuco completes its market entry and again generates a positive cash flow.

2006

Thomas Scheffel assumes total control of Sempuco as the sole shareholder.

2012

Sempuco is a service provider for rotary tables and milling heads, with the goal of making its customers more successful in the market.We meet our customers' requirements so that they are able to dominate the market. To this end, Sempuco has built up an extremely wide-ranging product system, comprising more than 1,000 product variants. For example, our modules are found in grinding machines - where as spindle carriers they have to satisfy extreme accuracy requirements, in large-scale boring mills and precision milling machines - where they can be automatically substituted from magazines, in volume machines - where they undergo customer-orientated modifications, through to complete offset slide units for milling machines and as large-scale assemblies.